Tata gigafactory ‘not enough’ to save industry but ‘a good start’ – Institute of Mechanical Engineers

Tata’s decision to build a new electric car battery plant in Somerset has been welcomed by the Institute of Mechanical Engineers. The institute said the gigafactory represents a “good start” in the drive to revive an ailing UK automotive sector, but emphasised the need for additional investment in order to support growth and EVs as part of the country’s decarbonisation strategy.

CC; Wikipedia

CC; Wikipedia Hella

Hella

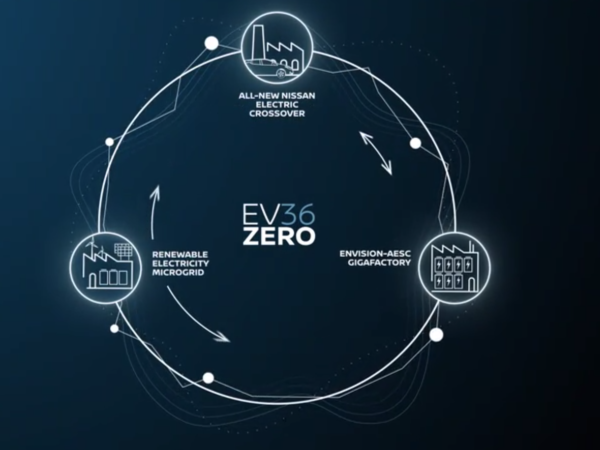

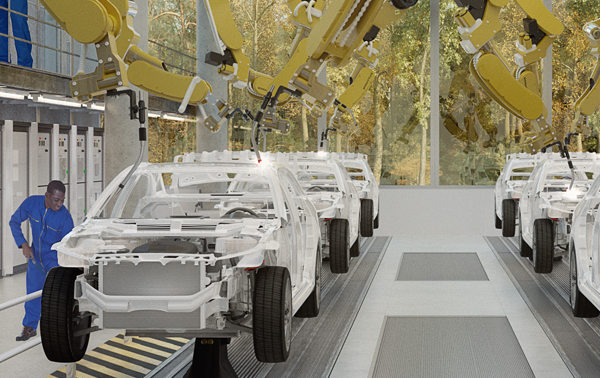

Nissan

Nissan InoBat

InoBat Britishvolt

Britishvolt Northvolt

Northvolt Gravity

Gravity