SRI: New technique for examining materials within tyre rubber

Observing sulphur cross-link density within SBR

Observing sulphur cross-link density within SBR

Working together with a Japanese university, Sumitomo Rubber Industries, Ltd. (SRI) has established a new technique for observing materials contained within tyre rubber. This process differs from existing methods as it enables an evaluation of the actual rubber used in mass-produced tyres rather than relying upon processed test samples. The company behind the Falken tyre brand foresees the technique facilitating the development of tyres with superior performance characteristics.

The rubber used in vehicle tyres is made up of dozens of different types of materials, including polymers such as natural and synthetic rubber as well as reinforcing agents such as carbon and silica. These materials form complex, hierarchical structures within the rubber.

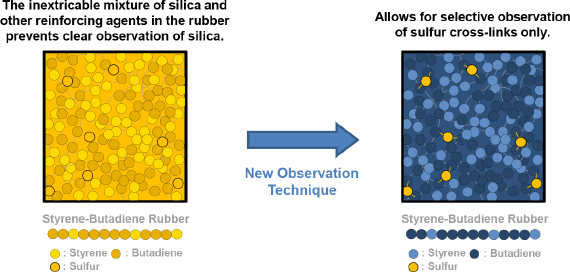

Explaining why it sought a new technique for examining these materials, SRI says: “In order to improve overall tyre performance, it is thus necessary to gain a clearer understanding of these hierarchical structures by observing the structures of each of the materials that make up tyre rubber in isolation.” In particular, the structures formed by sulphur cross-links, which give rubber its elasticity, have long been thought to be closely related to rubber strength as well as degradation and other changes that occur to rubber properties over time. SRI comments that until now, the details of these structures within rubber have “remained shrouded in mystery”.

The technique utilises a particle beam microscope recently developed by Ibaraki University. Together with the university, SRI has demonstrated the possibility of observing the density of sulphur cross-links in rubber. In contrast to conventional observation techniques that only provide image data that shows an inextricable mixture of sulphur and other reinforcing agents, this new technique generates clear images in which specific compound components, such as silica cross-links or other reinforcing agents, are each assigned specific colours.

“By allowing us to evaluate the very structures of tyres themselves, this image data can be used to come up with internal structures for tyres that will provide superior performance in terms of fuel efficiency, wear resistance and so forth. Thus, this new breakthrough creates enormous potential for the acceleration of the material development process.”

Comments