Developing cleaner tyres – ZF launches abrasion tester

The ZF Tread Wear Tester simulates real driving profiles in order to classify tyre wear behaviour at regular intervals

The ZF Tread Wear Tester simulates real driving profiles in order to classify tyre wear behaviour at regular intervals

Studies show the tyre/road abrasion caused by vehicles in motion contributes to microplastic and fine dust pollution, making this an issue our industry will increasingly have to consider in future. ZF Test Systems believes its new unit for testing tyre abrasion will enable tyre manufacturers to optimise their development programmes and offer cleaner tyres.

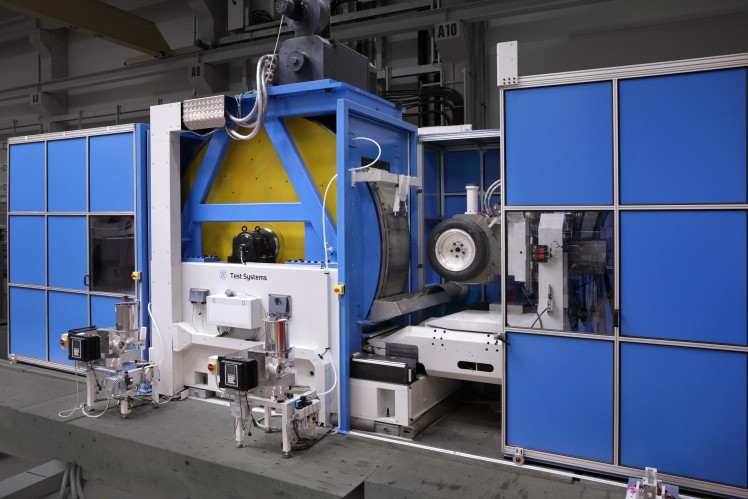

The ZF Tread Wear Tester simulates real driving profiles in order to classify tyre wear behaviour at regular intervals. In this way, it helps tyre makers to improve designs to reduce abrasion and minimise the resulting environmental pollution caused by fine dust and microplastics. ZF says this test bench thus represents a further step towards its ‘Vision Zero’ goal – a world without accidents and emissions.

ZF´s new Tread Wear Tester can be operated around the clock, seven days a week, regardless of weather conditions. Indoor testing allows for a more controlled simulation of temperature, driving speed and road surface, and removes driver influence as a variable. The Tread Wear Tester also enables previously-defined route profiles to be simulated. Tyres are measured at regular intervals during the test cycle to determine abrasion.

Tread Wear Mapping System for more flexibility

The Tread Wear Tester utilises a new, ZF-developed measurement system that enables laser measurement in the high-frequency range. The ZF In-Line Tread Wear Mapping System measures abrasion in the tread area at predetermined mileages using triangulated lasers positioned behind the tyre. Measurement is completely automatic, as it is no longer necessary to remove the tyre from the machine for separate measurement. The tyre rotates at a low speed during measurement and the triangulation laser system measures abrasion laterally, either in a single continuous movement or in stages. The sensor can be adjusted radially to accommodate the measurement of different tyre sizes.

Tyre wear testing typically takes place on the road and involves numerous vehicles and drivers over multiple days or weeks. Relocating testing to an indoor test bench considerably reduces the amount of fine dust pollution (resulting from both exhaust emissions and tyre abrasion) and CO2 generated during the tests. The fine dust caused by abrasion on the test bench is directly extracted, measured and cleaned.

Replicating road conditions with powder

The inclusion of a ‘Powder Supply Unit’ enables the natural friction caused by substances lying on the road, such as dirt and dust between the tyre and road surface, to be realistically simulated. Test times can be reduced by controlling the dosing of this powder. The Powder Supply Unit is situated above the tyre and releases the powder in a trickle directly between the drum and the tyre.

Specifications

The Tread Wear Tester accommodates the simulation of various driving modes that can be adapted to customer-specific driving cycles. The maximum test speed for passenger car tyres is 180 km/h and for bus and truck tyres 160 km/h. Load adjustment, the pressure the test bench applies to the tyre, is up to 25 kN for passenger car tyres and up to 60 kN for bus and truck tyres. The camber angle is +/- 8 degrees and slip angle +/- 10 degrees; this unit is based upon a six-component platform and enables cornering to be realistically simulated.

Linings for the three-metre drum can be replaced at any time. These linings can either be designed according to customer specifications or selected from the ZF portfolio. Their purpose is to simulate various road conditions.

- The ZF Tread Wear Tester simulates real driving profiles in order to classify tyre wear behaviour at regular intervals

- The fine dust caused by abrasion on the test bench is directly extracted measured and cleaned

Comments