Continental opens 3D printing competence centre

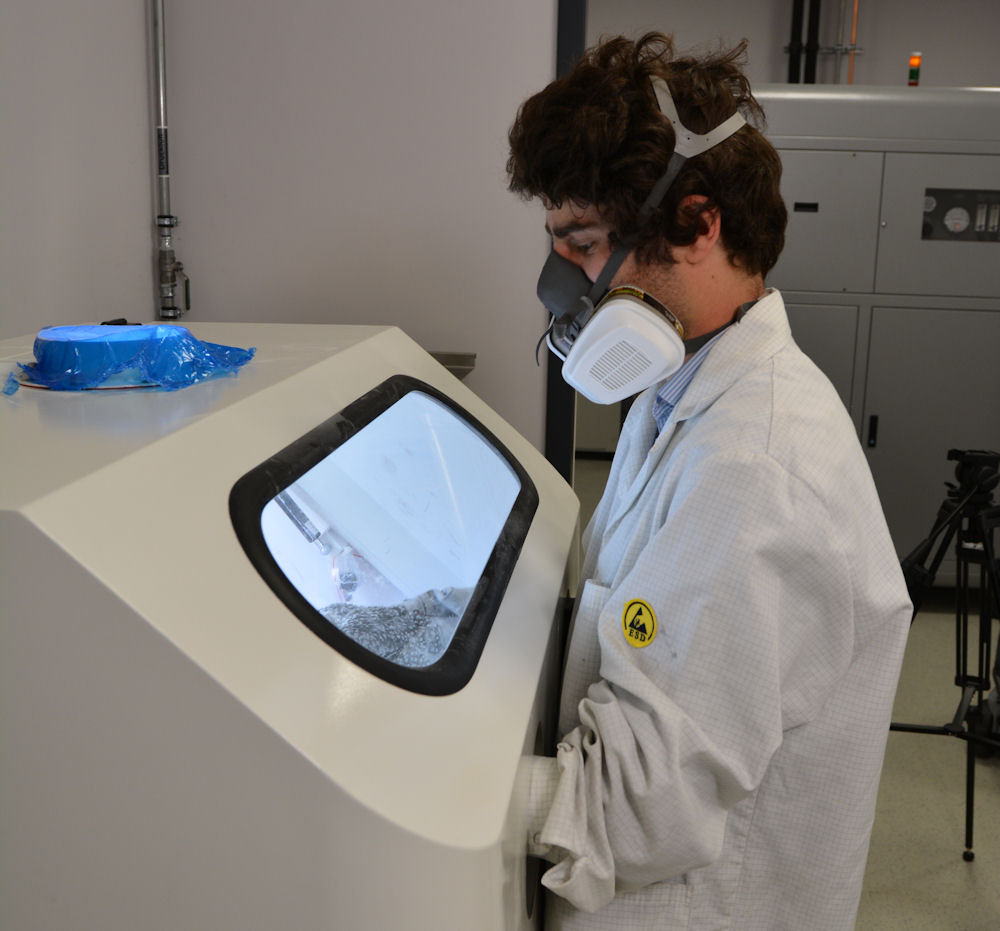

Selective laser sintering is a 3D printing method for plastic

Selective laser sintering is a 3D printing method for plastic

Continental’s Tire division is just one company division expected to benefit from the opening of a new competence centre for 3D printing. The facility, located at the Continental Engineering Services plant in Karben, Germany, offers a variety of modern 3D printing technologies, such as a Selective Laser Melting (SLM) machine, Selective Laser Sintering (SLS), Stereolithography (SLA), Digital Light Printing (DLP) and Fused Deposition Modelling (FDM).

“3D printing is becoming more and more important thanks to its many advantages. This is reciprocated by the ever-increasing demand for additively manufactured parts,” comments plant manager Torsten Rauch. “With our competence centre in Karben we are now able to test technologies, develop processes and procedures and roll out our production worldwide.”

The 3D printing process, also known as additive manufacturing, involves applying material layer by layer to create three-dimensional objects such as callipers, fluid reservoirs and water pumps. Whether prototypes, samples, spare parts or tools, printed components made of aluminium, for example, are now comparable in terms of durability and appearance to traditionally manufactured parts.

“We make 3D scans of the components, edit them followed by printing them with the desired material,” elaborates Stefan Kammann, head of the Additive Design and Manufacturing business segment within Continental Engineering Services’ Product Solutions division. “For example, we are able to produce a high-quality metal part in place of a plastic part. Furthermore, design changes can be handled flexibly depending on the product. The process lowers production costs with shorter production times.”

In addition to serving all Continental divisions, the competence centre can also be utilised by external partners.

Comments