Latest Hunter machines provide multitasking, efficiency benefits – Pro-Align

Hunter’s Revolution WalkAway allows technicians to automate tyre changing to increase multitasking

Hunter’s Revolution WalkAway allows technicians to automate tyre changing to increase multitasking

Latest tyre changer allows technicians to automate significant portion of task, while new Elite balancer increases efficiency

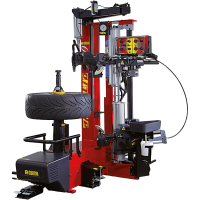

For garages looking to increase the number of revenue-generating tasks they can complete, the increased efficiency of their equipment is of paramount importance. Most directly, changing a tyre more quickly and safely means more customers can be served – and of course billed. But the latest changer from Hunter, distributed in the UK by Pro-Align, offers the chance to increase the additional tasks its operator can complete through increased automation of the process.

New to the comprehensive range of Hunter wheel servicing equipment, the Revolution WalkAway is a fully-automated tyre changer does not need a technician in attendance to operate the equipment throughout the entire process. By providing 80 seconds of unattended bead breaking and demounting, Pro-Align states, technicians can multitask, carrying out other work such as wheel balancing while other tyres within a set are being demounted. Hunter estimates that with the new WalkAway, the process of changing and balancing a complete set of four identical wheel and tyre assemblies is 25 per cent faster than traditional methods. It builds upon the legacy of the previous Hunter Revolution changer.

“Hunter’s engineers are always looking for innovative ways to deliver workshop efficiency gains and the new Revolution WalkAway epitomizes this approach,” comments Paul Beaurain, managing director at Pro-Align. “After carefully analysing every element of the tyre replacement process, the WalkAway allows technicians to carry out multiple processes simultaneously by using the autonomous demounting capability. This helps save a considerable amount of time changing each set of wheels which not only improves workshop efficiency but also the customer experience.”

Pro-Align is targeting workshops who are changing a large number of end-of-life tyres in sets of four or two of the same size of wheel and tyre assembly with the new Revolution WalkAway. After “teaching” the WalkAway on the first tyre, the demounting process is much simpler and technicians simply need to load the assembly onto the machine, orient the TPMS, activate WalkAway and finally offload the tyre. A helpful status light indicates when the machine is in operation, has stopped or requires operator input. The simplicity of the system means that operators have to make just four critical decisions during the overall operation. Pro-Align compares this with 17 critical decisions it has identified when working with conventional changers, streamlining training and improving ease of use.

“Essentially, the new WalkAway gives workshops added tyre changing capacity without any investment in extra equipment or additional space requirements,” adds Beaurain. “Not only can more jobs be completed in the same time by the same number of technicians but customers will also receive a faster service.”

Balancing act

The Hunter Road Force Elite measures tyre forces

The increased emphasis on ride comfort in modern car development has meant that the impact of minor problems such as wheel vibrations can be significantly magnified for drivers. While this would be the case without considering external factors, the UK’s much-publicised lack of investment in fixing deteriorating road surfaces leading to a major pothole repair backlog recently addressed by the latest budget means that wheel vibration problems are likely to continue. And with the potential for a continued bumpy ride economically, the chancellor was careful to warn that measures to resolve the pothole pandemic are potentially imperiled by a pessimistic prognosis post-Brexit. Therefore, there is a significant opportunity for garages best placed to fix the inevitable ride-based problems picked up on the UK’s less than ideal road surfaces.

Pro-Align argues that in many cases, traditional wheel balancers cannot solve the most challenging of wheel vibration issues, often leaving customers frustrated or out of pocket when they are ultimately forced to buy a new set of tyres. However, the company adds that its newest Hunter technology can diagnose and solve these issues, with solutions provided in “less time than a standard wheel balance”.

The latest version of the US garage equipment supplier’s wheel balancing range topper, the Hunter Road Force Elite (RFE) diagnostic balancer can provide a fast, first-time fix to the problem.

The RFE differs from standard balancers as it measures tyre forces known as road force variation (RFV) and lateral force (LF) to conduct a full diagnostic of the wheel and tyre assembly. It does this by scanning the wheel rim and applying a load via a roller to take the wheel and tyre assembly on a simulated road test. Once RFV is identified, the balancer provides a ‘ForceMatching’ recommendation which matches the stiff spot on the tyre with the low spot on the wheel rim, minimising any vibrations to give a smoother ride. Where LF is identified due to conicity of the tyres, the RFE even advises of the best position on the vehicle to counteract it for a straighter drive.

The new ‘vision’ rim scan technology, which is only available on the very latest version of the Road Force balancer means the use of any balance weights can be minimised and placed more effectively for a more accurate balance. With the identification of spoke locations via the scan, the weights can also be hidden behind spokes resulting in a more aesthetically pleasing solution. Furthermore, the RFE’s in-built HunterNet system allows results to be emailed to customers directly, giving further evidence of a job well done.

Hunter’s latest premium wheel balancer

Comments