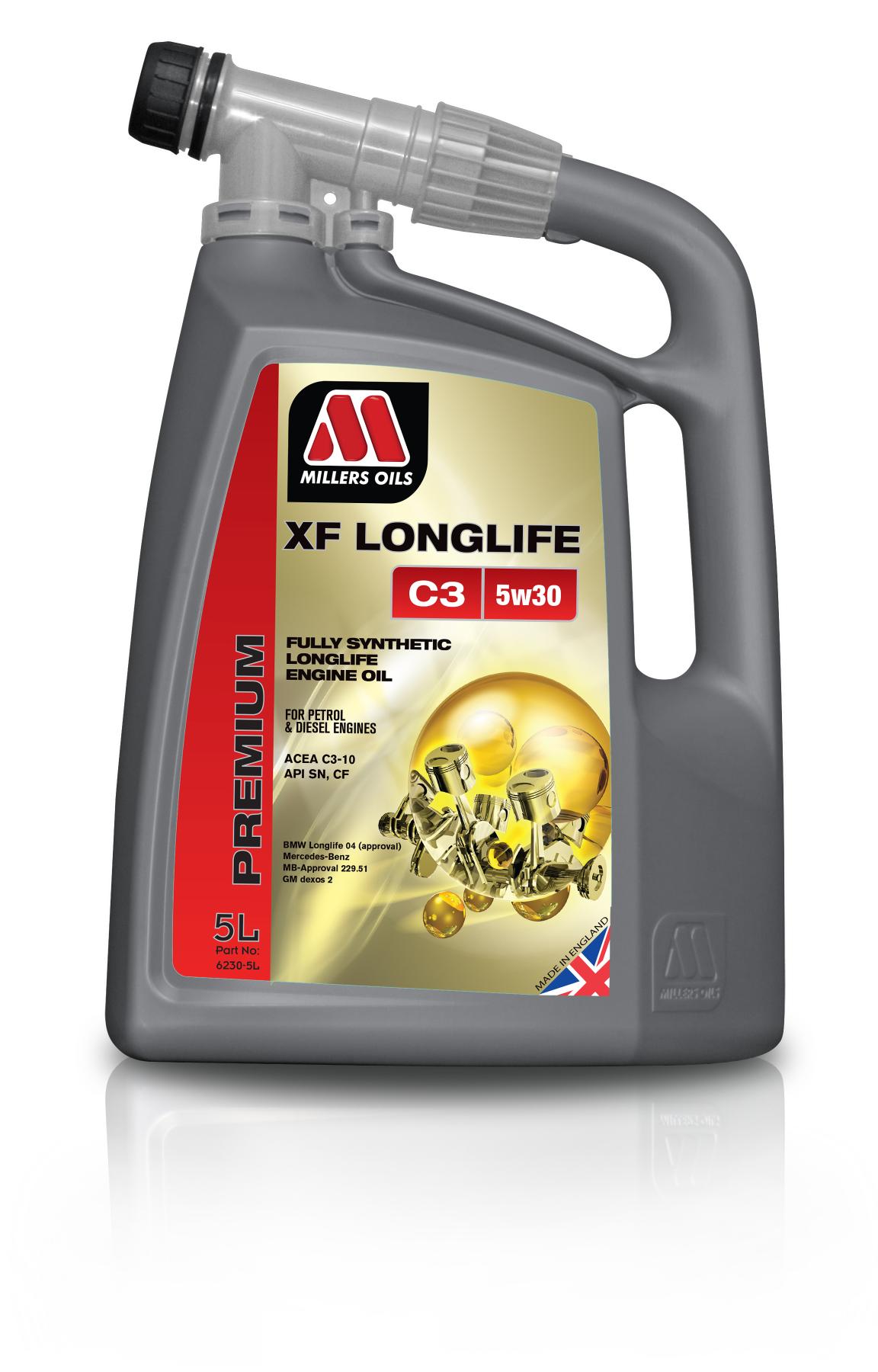

New bottle design prevents spills and contamination, says Millers Oils

The new bottle design aims to reduce contamination in workshops using multiple types of engine oil

The new bottle design aims to reduce contamination in workshops using multiple types of engine oil

Specialist oil developer and producer Millers Oils is launching its Flowcontrol bottle to worldwide markets at Automechanika Frankfurt this week. The company says the container features an easy-pour mechanism that enables users to control oil flow without the use of a funnel, thus preventing contamination and, of course, spills. In June 2014, the month that the new bottle design was introduced into the UK market, Millers Oils says its two local distributors experienced a 95 per cent year-on-year sales increase – a phenomenon it says was driven by the Flowcontrol bottle.

The design follows Millers Oils’ recognition that the complexity of automotive lubricants has led to a situation where garages need to stock 15 or more types of engine oil, typically stored in five litre bottles. In particular, the manufacturer identified a reoccurring issue when speaking with garage workers – customers returning their cars after a service due to smoke from spilt oil. The new Flowcontrol design addresses this problem by preventing glugging and enabling the technician to control the flow of oil more easily.

“We have seen oil varieties expand and the price of crude oil rise significantly over recent years, increasing garages’ investment in stock considerably,” says Mark Berry, business development manager – automotive, Millers Oils. “Twenty years ago a garage may have only stocked three or four drums of oil, each containing a different grade, now a garage has to stock 15 or more varieties, typically in five litre bottles, which necessitates the use of funnels. The easy-pour bottle allows technicians to control the flow of oil, preventing spillage which can cause smoke, a sickly smell and lead to customer returns. The new mechanism also reduces the risk of contamination that can occur when using funnels, mitigating the risk of damage to components.”

The complexity of oil grades is not limited to engine lubricants, but has also affected the number of gear oils garages need to stock, increasing the figure by a factor of four. This diversification means that further lubricant training and technical support is becoming a necessity for garages and their suppliers to prevent contamination or the use of incorrect oils, which can be costly for both the customer and the garage. Using contaminated engine oils can cause expensive issues such as turbo failures, or clogged DPFs, costing the garage large sums to fix. Millers Oils currently provides a technical support line and online look-up service for garages, their suppliers and customers. The company will also introduce training events and workshops in the near future to provide the technical support the aftermarket requires.

“Due to the development of automotive oils over recent years, an improved knowledge of the market and technology is now required by garages and their suppliers to avoid expensive mistakes,” says Berry. “We aim to provide these professionals with the technical support they require as quickly as possible through our support services and training, allowing them to find the right grade of oil quickly and efficiently.”

Following the launch, the Flowcontrol bottle will be available worldwide across the Millers Oils range of premium engine oils.

Comments