The importance of SAS reset in alignment servicing

Resetting steering angle sensors is an important part of the wheel alignment process

Resetting steering angle sensors is an important part of the wheel alignment process

Supplier of Hunter garage equipment in UK, Pro-Align has explained the importance of resetting steering angle sensors (SAS) – a service that is part of the wheel alignment process. Failure to reset the SAS after an alignment can affect the correct operation of electronic driver-assist systems that rely on precise steering information from the SAS.

Changing wheel alignment service requirements

As vehicle technology and design have evolved over time, so has the requirements of wheel alignment servicing. Prior to the late-1970s, alignment servicing consisted of measuring and aligning only the front wheel toe angles. Subsequent steering and suspension design evolution lead to a number of wheel alignment advancements such as measuring of individual rear toe and total four-wheel alignment.

Until recently, when a four wheel alignment check and subsequent adjustments had been made (ensuring a level steering wheel had been obtained), this used to be the end of the job – but not any more.

For the millions of modern vehicles which are now equipped with Steering Angle Sensor (SAS), this is no longer the case and as specified by many OEMs, the additional step of resetting the SAS is essential and a stated requirement to complete the job properly.

The work of the SAS

Steering Angle Sensors monitor the driver’s input by continuously measuring the position and turning rate of the steering wheel, feeding back information to a number of on-board vehicle systems.

The SAS works as part of a complex network of sensors on the vehicle that track aspects such as wheel speed, lateral forces, vehicle roll, and along with the data provided by the SAS, are used to control driver-assist systems including Electronic Stability Control, Electric Power Steering, Active Steering and Lane Departure. However, for each of these safety critical systems to operate effectively, it is essential that they “know” the driver’s intended steering direction and turning force.

During the wheel alignment service, mechanical adjustments to the vehicle’s steering and suspension system will correct any errors in the vehicle’s thrustline. However, for vehicles equipped with a SAS an electronic reset is also needed to match the new vehicle thrustline as the position of the SAS will be unknown after an alignment. Therefore many OEMs now specify that measuring and resetting the SAS is now the additional final step of an alignment service.

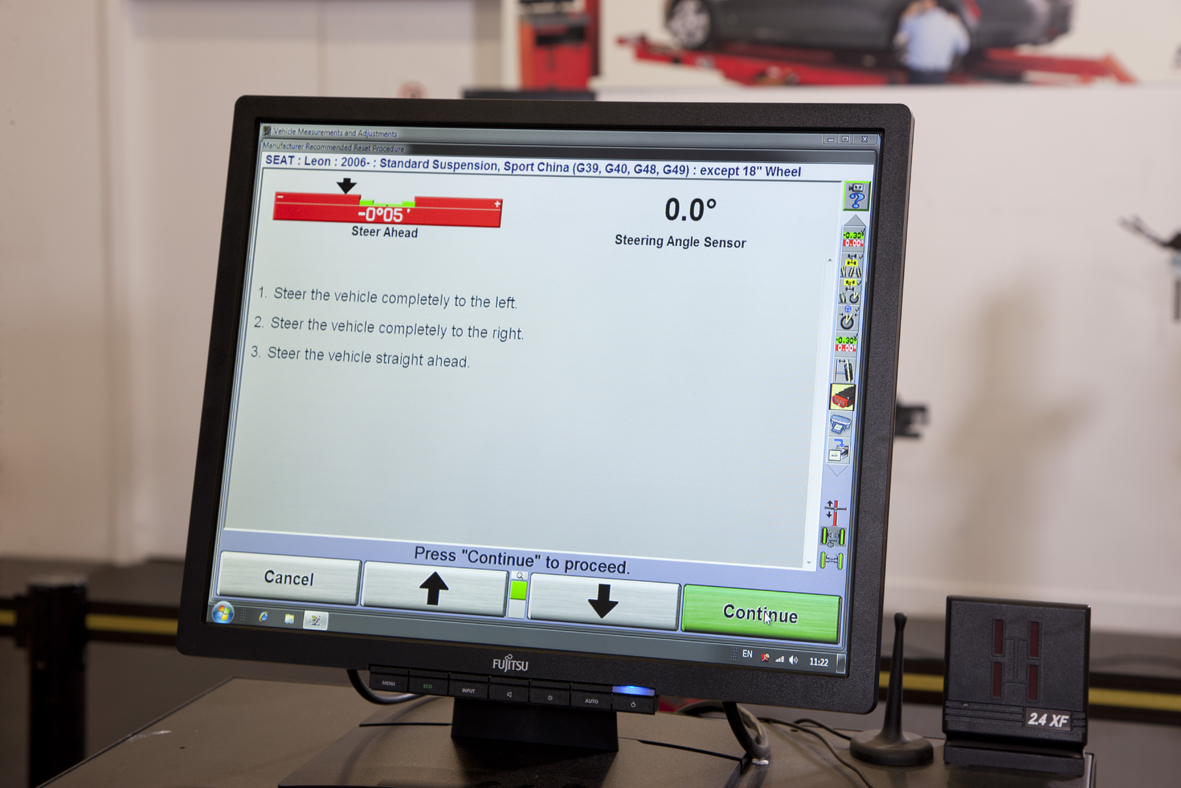

The CodeLink module plugs into the vehicle’s OBD-II port and communicates directly with the alignment console

Many OEM diagnostic tools include the functionality for workshops to reset the SAS at the end of the alignment job. However, Pro-Align explains that workshops using its Hunter HawkEye Elite TD and the optional CodeLink module can take advantage of the system’s fully integrated SAS reset solution. The CodeLink module simply plugs into the vehicle’s OBD-II port and communicates directly with the alignment console to guide technicians through the process. Not only is functionality seamlessly integrated but the results printout also includes details as proof and confirmation that the SAS reset has been completed in line with the vehicle manufacturer’s specifications.

With a growing number of sophisticated driver-assist systems and vehicles fitted with a steering angle sensor, it’s increasingly important that workshops are properly equipped to service these vehicles properly.

Comments