PAS 3100 remanufactured parts specification published

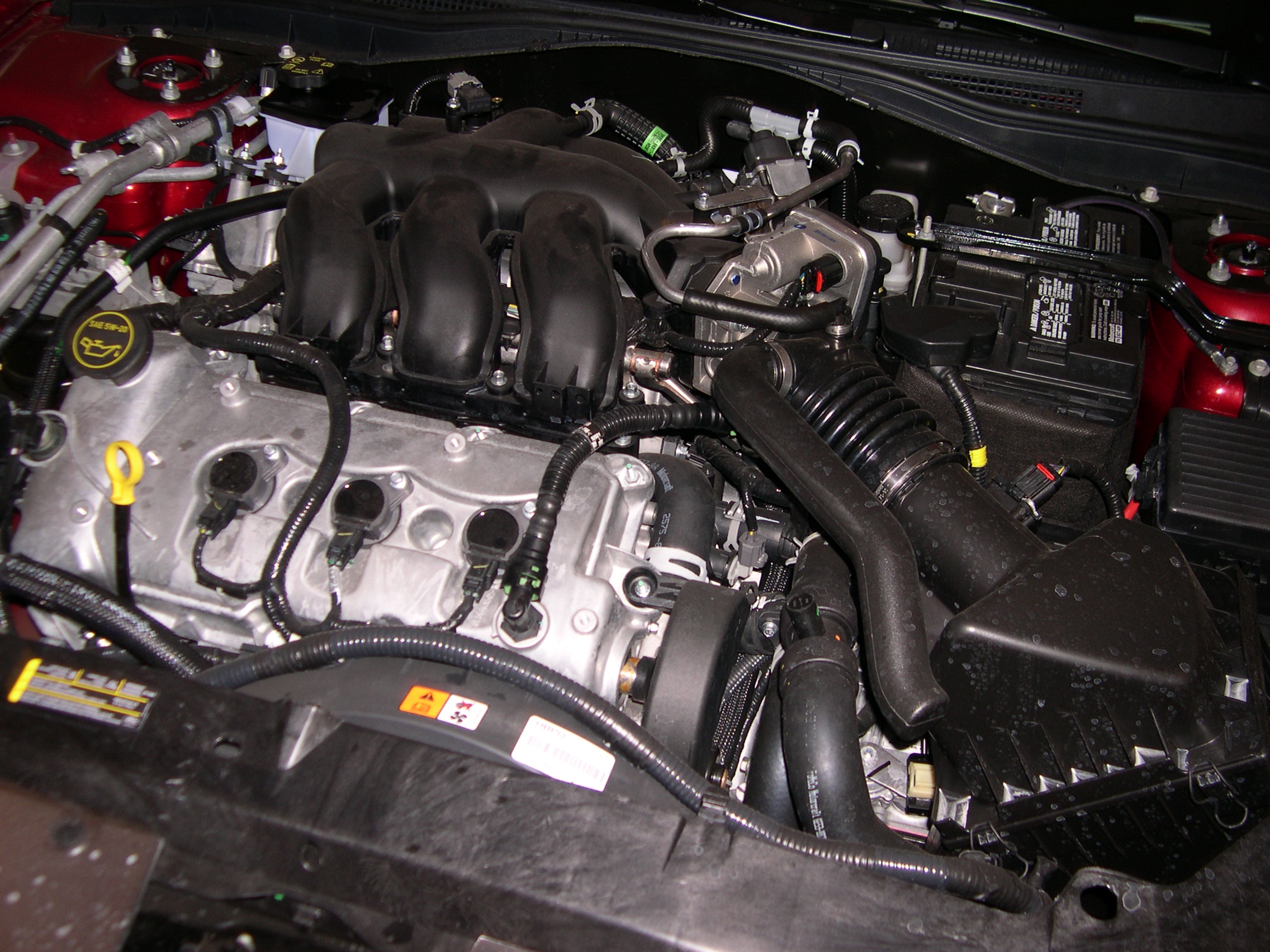

Remanufacturing car parts fits in with the political, environmental and economic agendas. Now it has published its PAS 3100 standard, BSI makes the case that there is now an effective and consistent way to do it

Remanufacturing car parts fits in with the political, environmental and economic agendas. Now it has published its PAS 3100 standard, BSI makes the case that there is now an effective and consistent way to do it

BSI, the UK standardisation body published a specification for remanufactured parts developed in collaboration with Honest Co Ltd. from Japan. According to the two organisations, PAS 3100 remanufactured automotive – as the specification is known is designed to “clearly identify what terms define remanufactured automotive parts, as well as identifying a verifiable way to establish level of quality.” It has been developed to be used independently of other quality management systems or standards such as ISO 9001 but can be used with one if desired.

Currently, remanufactured automotive parts, even ones that have identical parts and carry the same part number, can differ greatly in performance and durability. This is because the pattern and length of previous use varies considerably. Additionally, some parts are placed on the market as “remanufactured” having only had minimal refurbishment such as cleaning and re-painting, and have undergone no remanufacturing process. Therefore the quality level of remanufactured parts in the market is currently very wide. It can be difficult to distinguish between those parts that are likely to deliver value for money and those that are not. As such, many parts do not meet expectations and this has inhibited growth in the remanufactured parts market. However cost, waste reduction and C02 benefits continue to support demand.

The introduction of a new remanufacturing specification also plays into the wider political agenda. This context centres around the “End of Life Vehicle Directive” we have all come to know and love. This directive sets a target of 85 per cent reuse and recycling and 95 per cent reuse and recovery by 1 January 2015. One report produced by the Scottish government in mid-2013 put current UK performance at approximately 85 per cent reuse and recovery of End of Life Vehicles (See “Remanufacture, refurbishment, reuse and recycling of vehicles: Trends and opportunities” produced by Optimat on behalf of the Scottish Government, June 2013 for complete details). A further clause dictates that 85 percentage points of the 95 per cent figure must be reuse and recycling as opposed to other methods of disposal such as landfill. All this means that one of the key issues for the sector is how to extra 10 per cent reuse and recovery will be achieved. Currently the proposed of materials not reused or recovered are contained within waste output from shredders known as Automotive Shredder Residue or simply Shredder Residue (as it contains residue from other input materials such as waste electrical and

electronic equipment). In short, it all points to an urgent need to increase rates of automotive reuse and recycling and the remanufacturing of parts is a key way of doing this. Until now, this has been challenged by the lack of any third- party comparability in this process.

The specification itself

PAS 3100 covers requirements for a process control system for the remanufacturing of automotive parts. It aims to clearly and unambiguously define the terminology used to describe “remanufactured automotive parts.” It also specifies an objectively verifiable process that can ensure the remanufacture of automotive parts is to a standard equivalent to that of manufacturers’ original parts.

The kind of closed loop system the government would like to see more of

Features of PAS 3100 include: Methods and constituent tasks; Competence of personnel; Tools and equipment; Materials and controlled consumables; Remanufacturing process management; Quality control Health and safety of personnel; and Control of environmental impact of remanufacturing processes.

Dan Palmer Head of Market Development for Manufacturing & Services at BSI said: “This specification is not just about enabling organizations and individuals involved in the remanufacturing of used automotive parts for sale and use, to be clear about the performance history of the products they work with. It is about maintaining a high level of quality too, to improve reliability for the end users of these parts.”

Some of the organizations from Japan and the UK who helped collaboratively develop PAS 3100 include: APRA Europe (Automotive Parts Remanufacturers Association), Aviva UK, BVSF (British Vehicle Salvage Federation), CRR (Centre for Remanufacturing and Reuse) and Suzuki GB PLC. Direct Line Group, Ford Motor Company Limited, Jaguar Land Rover, Morris Associates and SMMT (The Society of Motor Manufacturers and Traders Limited) were also involved in the process.

Mr Nagatsuka, President of Honest Co Ltd. Japan said: “We urge manufacturers to apply this PAS 3100 to all automotive parts remanufacturing. It will help to ensure that high quality products are supplied to the market and enhance the performance and reputation of the automotive parts remanufacturing industry. This will also increase the satisfaction of end users and contribute meaningfully to the improvement in the global [market].”

Comments