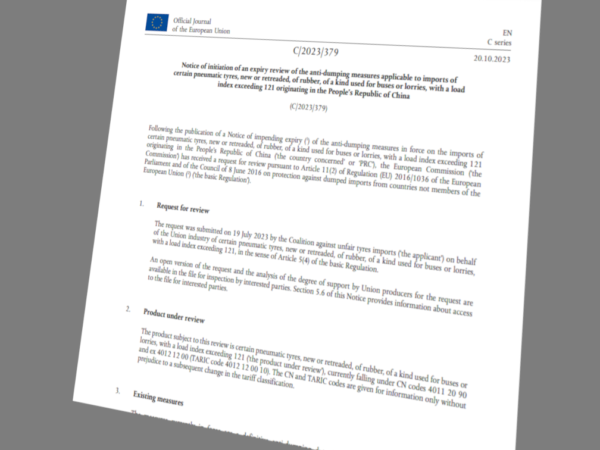

US launches sunset review investigation into Chinese-made TBR

On 2 January, the US Department of Commerce announced that it would launch the first anti-dumping and countervailing sunset review investigation into truck and bus tyres (TBR) imported from China. Stakeholders should register a response to the US Department of Commerce before January 12 (within ten days from the date of the announcement). According to the China Rubber Industry Association, the North American trade union organisation USW (United Steelworkers) has submitted a registration to respond.

Yuval Zukerman; Unsplash

Yuval Zukerman; Unsplash

Renaldo Matamoro; Unsplash

Renaldo Matamoro; Unsplash

S. Hermann & F. Richter; Pixabay

S. Hermann & F. Richter; Pixabay

Christian Lue; Unsplash

Christian Lue; Unsplash ChutterSnap; Unsplash

ChutterSnap; Unsplash

Sumitomo Rubber Industries

Sumitomo Rubber Industries Stephen Goodchild; Tyre Industry Publications Ltd

Stephen Goodchild; Tyre Industry Publications Ltd