Rubber processing: Toyo employing materials informatics technology

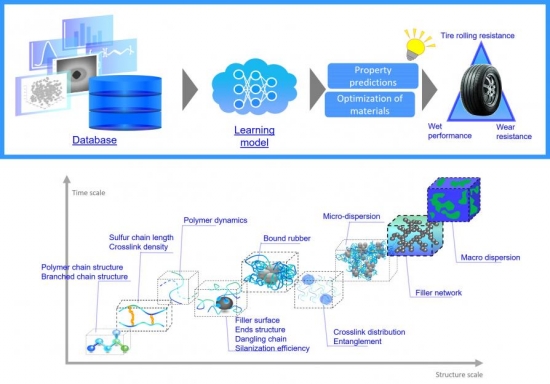

An example of predictive modeling applied to the material structure of rubber

An example of predictive modeling applied to the material structure of rubber

Toyo Tire Corporation says it is employing materials informatics (MI) in its tyre development to predict the properties and optimise the material structure of the rubber materials it works with. The tyre maker explains that MI technology uses artificial intelligence and other technologies to “enable the discovery of new and alternative materials with greater efficiency than conventional methods.” MI is a component of Toyo Tire’s ‘Nano Balance Technology’ rubber material development platform, and was realised in collaboration with SAS Institute Japan.

Machine learning capabilities such as artificial intelligence and other technologies have increasingly been used in the material development process in recent years, but Toyo Tire believes MI technology is about to change the field of material development, a task that has typically been a very time-consuming process of trial and error process that relies on the experience of engineers and repeated experimentation.

Since 2018, Toyo Tire has been using MI technology, based on its accumulated data assets, to validate the predictive technology and physical properties of its compound ‘recipes’. Improvements to the technology’s precision implemented last year enables the company to additionally validate the expanded application of the target data, such as linking it to external information. Going forward, Toyo Tire intends to develop an environment where its in-house data can be put to full and effective use. “We will also use novel analysis methods and predictive data to realise new materials that use MI technology, which highly optimises development, to develop high-performance products while at the same time reducing the time and cost of development.”

Compound recipe development using data resources

Rubber compounds are a composite formed by adding filler and other ingredients to the base material polymer. Each ingredient directly affects the characteristics of the product, thus requiring high levels of control over the type and quantity of ingredients, as well as adjustments in the processing method.

The introduction of MI technology allows Toyo Tire to build a system that creates highly accurate predictions of properties and recipes, which enables efficient material development with minimal testing. The system implements a nonlinear regression model, which can make expanded predictions that go beyond existing knowledge, by importing external information to a database. This system will also be used in the development of high-performance materials.

Using digital technology to develop new materials

Nano Balance Technology draws on a number of tools that evaluate the elements of material properties by each hierarchical structure. Toyo also uses the technology to extract development issues. Data for material and chemical structures obtained by analysis is entirely different from material property data. Therefore, data for material and chemical structures has mainly been used as information to indirectly predict material properties. Adopting the newly-developed MI technology to material analysis makes it possible to calculate prediction values of material properties from structural information. As the technology lends itself to the inverse problem of optimising the structure according to targeted property values, Toyo Tire intends to apply and expand it to the field of new material development.

Comments